Evolutionary Design Principles Towards Impact-Resistant Biomimetic Nanocomposites

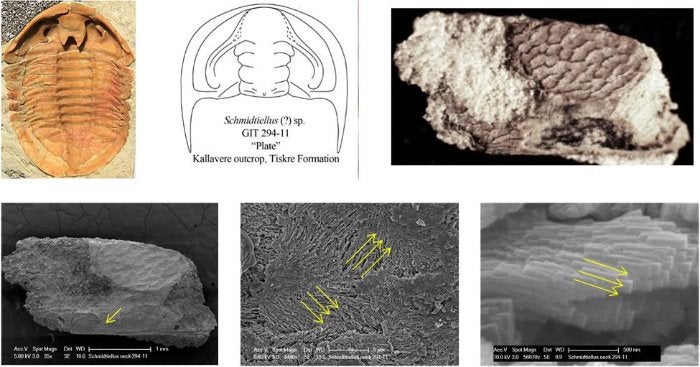

Investigation of Cuticle Structure of Trilobites – A Fossilized Species

In collaboration with Professor Nigel Hughes, UC Riverside

Trilobites are a fossil group of earliest known extinct marine arthropods. This species first appeared in Early Cambrian period ~520 million years ago, flourished through Paleozoic era before declining to extinction during Devonian era, and finally disappeared in the Permian period ~250 million years ago. These arthropods survived for a long time (~270 million years) which encouraged our group to investigate the structural features of the animal cuticle that facilitated their lengthy time span. Specifically we are investigating the cuticle structure of an early trilobite, called Schmidtiellus, which appeared ~520 million years ago. Initial evidence suggests a helicoidal-like cuticle structure or perhaps a lamellar-to-helicoidal structural transition consisting of unidirectional rod-like crystals in these species. Fourier transform infra-red spectra suggest mostly mineralized structures containing hydroxyapatite (calcium phosphate) crystals. Further characterization such as Synchrotron X-ray Diffraction is in progress to confirm such helicoidal structures which could indicate the origin of helicoidal structures in biological species.

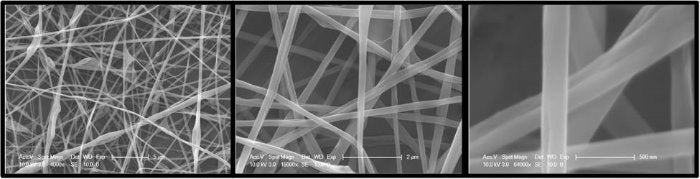

Electrospun Spider Silk Fiber from the Extracted Gland Precursor

In collaboration with Professor Cheryl Hayashi, UC Riverside

Spider silk, a widely investigated natural light-weight material, is known for its high strength and ductility (even stronger than steel by weight). This unique combination of mechanical properties in silk fibers is attributed to interplay between hard crystalline domains of alanine and soft amorphous matrix of glycine blocks. Attempts have been made to synthetically generate liquid precursor replicating the protein sequence of the spider silk gland dope and then subsequent processing to fabricate artificial spider silk fibers. In our group, we are attempting to fabricate spider silk fibers from an organic solution of the spider gland dope using electrospinning. In electrospinning, a solution is allowed to flow through a metallic needle and a high electrical voltage is applied between the tip of the needle and a metal collector. When the applied voltage exceeds a threshold value, a liquid jet is formed which upon subsequent solvent evaporation forms fibers at the collector. Controlling the voltage, solution flow rate, and needle-to-collector distance, our group has successfully fabricated electrospun spider silk that are about an order of magnitude thinner than natural spider silks. Decreased fiber size could mean even higher strength and toughness of spider silk than reported earlier. We aim to fully characterize the electrospun spider silk fiber for their structure and mechanics using multiple techniques such as TEM, XRD, Tensile testing and nanoindentation tests.